The Advantages of Automatic Gummy Molds

Unmatched Production Speeds and Efficiency

When it comes to productivity, nothing beats the speeds achieved with automatic silicone molds. A single machine can process hundreds of molds per hour, dramatically outpacing manual operations. The assembly line approach, combined with compressed air assistance for demolding, means operators can focus on quality control rather than repetitive tasks. This efficiency boost translates directly to your bottom line, with production rates that can transform a small operation into a powerhouse.

Precision Weight and Consistency

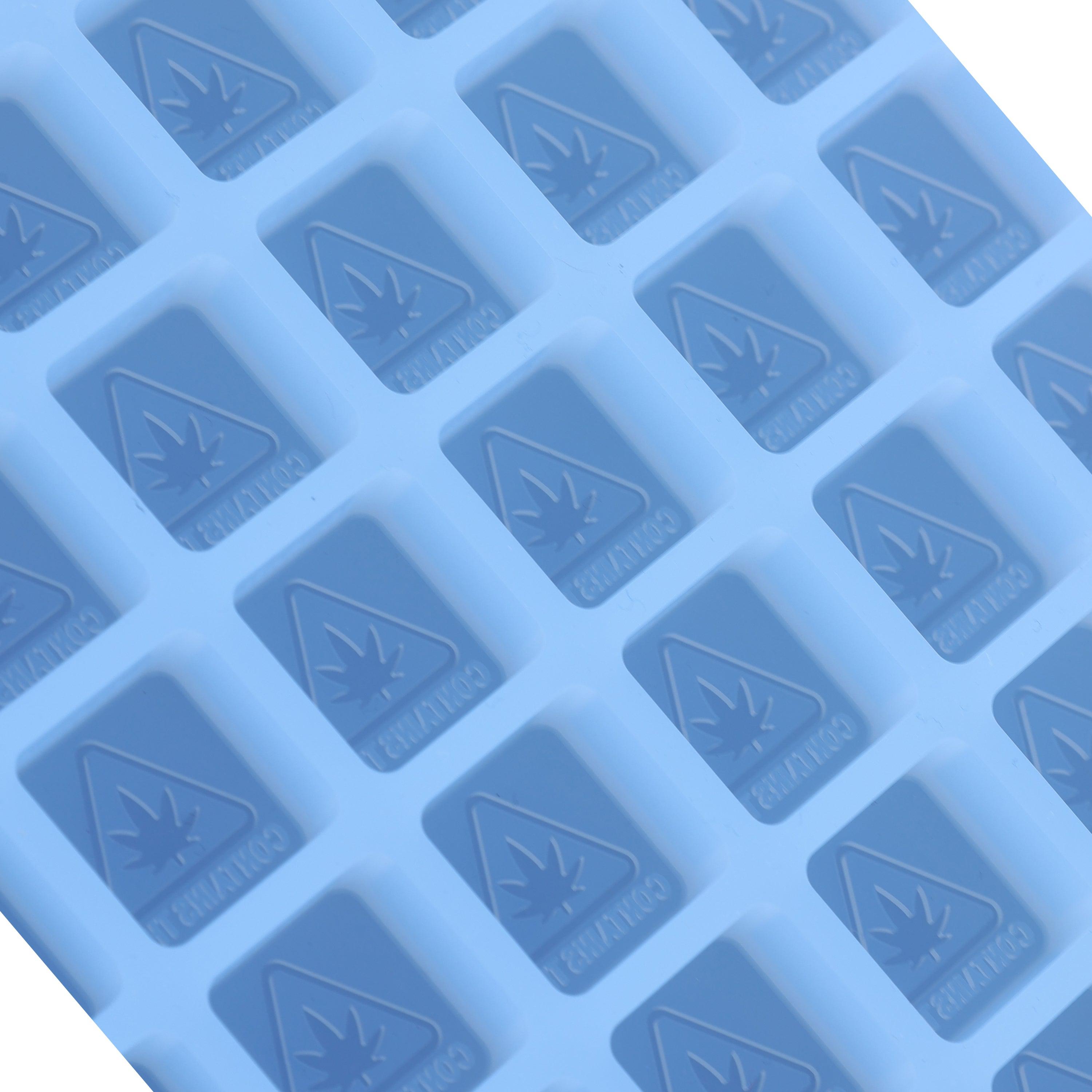

Gone are the days of irregular gummies and inconsistent weights. Each cavity in our custom trays is engineered to exact specifications, ensuring that every gummy meets the required standards. The automatic filling system maintains perfect dosing, while the silicone mold material provides the ideal release properties. This attention to detail is essential for THC edibles, where precise dosing isn't just about quality — it's about compliance and reliability.

Simple Operation with Maximum Flexibility

The beauty of our automatic system lies in its simple yet versatile design. The frame setup allows for quick mold change when switching between products, whether you're producing gummies, chocolates, or other candies. Optional add-ons and accessories make it easy to customize your setup, while the included standard features provide everything needed to get started. The approx length of time needed for training new operators? Just a few hours.

Enhanced Tunnel Integration and Workflow

Our automatic silicone molds are designed with the complete production flow in mind. The trays seamlessly integrate with standard cooling tunnel systems, creating a smooth transition from molding to finishing. This integration minimizes handling time and reduces the risk of product damage, ensuring your stock moves efficiently from production to packaging with minimal waste.

Shop Universal Silicone Molds & More Today!

Ready to transform your gummy production operation? Vector Molds' automatic silicone molds represent more than just an equipment purchase — they're an investment in your business's future. We understand that making the switch to automation can feel like a big step, but our team of experts is here to guide you through every aspect of the transition. From initial setup to ongoing support, we're committed to ensuring your success with our advanced molding systems.

Don't let manual production methods hold you back any longer. Join the ranks of successful manufacturers who have already discovered the difference Vector Molds can make. Contact us today to learn how our automatic molding solutions can revolutionize your production line and take your business to new heights. Remember, in the world of edibles manufacturing, those who embrace innovation today will lead the market tomorrow.